6-volt, 8-volt, and 12-volt batteries

6-volt, 8-volt, and 12-volt batteries

6-volt, 8-volt, and 12-volt batteries recommended rate and time for fully discharged condition ("flat discharged"). CAUTION: For low water loss batteries.

| Rated Battery Capacity (Reserve Minutes) | Slow charge | Fast Charge |

|---|---|---|

| 80 minutes to 125 minutes | 15 hours @ 3 amperes | 2.5 hours @ 20 amperes or 2.5 hours @ 20 amperes |

| Above 81 to 125 minutes | 21 hours @ 4 amperes | 3.75 hours @ 20 amperes or 1.5 hours @ 50 amperes |

| Above 126 to 170 minutes | 22 hours @ 5 amperes | 5 hours @ 20 amperes or 2 hours @ 50 amperes |

| Above 171 to 250 minutes | 23 hours @ 6 amperes | 7.5 hours @ 20 amperes |

| Above 250 minutes | 24 hours @ 10 amperes | 6 hours @ 40 amperes or 4 hours @ 60 amperes |

CAUTION! Batteries emit explosive gases while being charged. Before charging a battery review all safety precautions.

Observe all the following safety rules:

A discharged Superlex battery can be recharged. The purpose of the recharge is to convert the lead sulfate on the positive and negative plates back to lead dioxide (positive plate) and metallic or sponge lead (negative plate). During the conversion or charging process, the water in the electrolyte is converted into sulfuric acid by reacting with the sulfate in the plates. Before this conversion, no usable electric energy exists between the positive and negative plates.

A battery’s electric storage capacity is determined by design, age, temperature, discharge rate and an array of other factors. A battery’s capacity is maximized when all the convertible lead sulfates have been converted to lead oxide and metallic lead. When a battery has reached a full state of charge, any additional charging only produces wasted heat and the breakdown of water within the electrolyte into hydrogen and oxygen gasses. The excess heat is damaging to the plates (grids and pastes) and separators, whereas the breakdown of water lowers the electrolyte level and increases the specific gravity of the electrolyte. All of these factors contribute to shorter battery life.

Follow the charging guides of the battery charger if available. If they are not available, use the rates shown in the “Battery Charging Chart” shown in section on charging methods.

If time is available, the lower charging rates in amperes are recommended. The lower rates must be used if the battery is suspected of having a problem, i.e., to be sulfated or have a temperature below 15°F (-26.1°C).

NOTE: If a battery is to be recharged overnight (10-16 hours), refer to the specified slow charge rate. Don’t overcharge sealed batteries, for this increases water loss. The “Battery Charging Guide” tells you approximately how much recharge a fully discharged battery requires. However, a more accurate method of determining the amount of recharge a battery requires is as follows:

The best method to ensure that a battery is fully charged is to measure the specific gravity of a cell once per hour. The battery is assumed to be fully charged when the cells are gassing freely at a low charging rate and less than 0.003 change in specific gravity occurs over a three hour period.

When any battery is being charged, periodically measure the temperature of the electrolyte. If the temperature exceeds 125°F (51.6°C), or if violent gassing or spewing of electrolyte occurs, the charging rate must be reduced or temporarily halted. This is done to avoid damaging the battery.

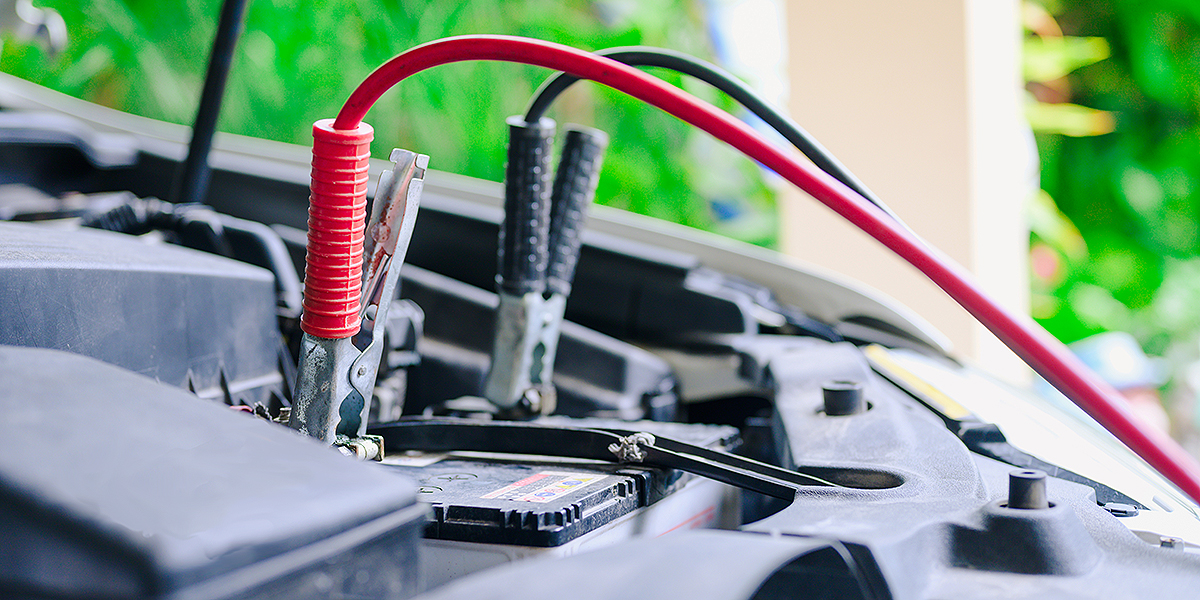

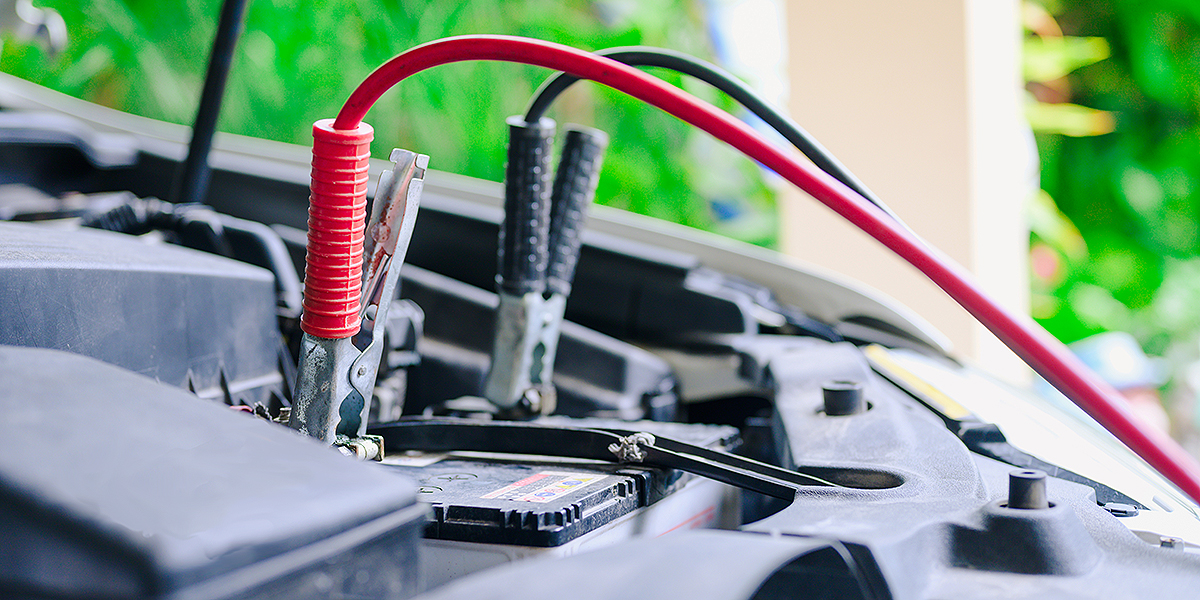

Before placing a battery on charge, clean the terminals if necessary. If needed, add enough water to cover the plates. Fill to the proper level near the end of charge. If the battery is extremely cold, allow it to come to room temperature before adding water because the level will rise as it warms. In fact, an extremely cold battery will not accept a normal charge until the temperature rises.

Batteries may be connected to the charging source in series, parallel or individually, depending upon the type of charger used. More than one battery (all must be of the same voltage) can be charged on high-rate fast chargers. When this is done, connect the batteries in parallel, i.e., connect the positive (+) terminal of one battery to the positive terminal of the next battery and negative (-) terminal of one battery to the negative terminal of the next battery, etc.

The number of batteries that may be connected in parallel depends on the current capacity of the charger. The output of the charger will divide equally among the number of batteries in parallel if they are identical (same rating, same state-ofcharge, etc.) and there are no high resistance connections. For example, if five batteries are being charged in parallel, and the charger output is 20 amperes, each battery will receive 1/5 of the total output, or 4 amperes.

A series connection is one in which the positive (+) terminal of one battery is connected to the negative (-) terminal of the next battery, etc. Each battery in the series connection receives the full current output of the charger.

The number of batteries that may be connected in series is dependent upon the voltage rating of the charging source. Batteries with different capacities can be charged in series, but the proper charge rate and charging time for the lowest capacity battery must be used.

Constant Voltage Charger

This type of charger charges a battery at a designed maximum charging voltage, usually above 13.8 volts and below 18.0 volts for 12 volt batteries. Sometimes this charging voltage can be adjusted. After a discharged battery has been recharged for a period of time, and the designed maximum voltage is reached, the battery charger controls the charging voltage at a constant level of this voltage. Initially, the charger will put out the maximum current and voltage demanded by the battery and the charging current may be high. As the charging continues, the battery’s demand for charging power decreases. If the battery charging voltage remains constant, the charging current will decrease to a minimum when the battery is fully charged. Once the battery is fully charged, its capacity is maximized, and there is no more active material to be converted. Any excess current after this point results in increased battery temperature and gassing.

Constant Current Charger

This type of charger charges a battery at a preset or adjusted rate of constant current. While being charged by a constant current charger, the battery voltage will rise as the state of charge increases. The voltage rise of each battery under charge has a natural limit, usually lower for the antimonial alloy batteries and higher for calcium alloy (maintenance-free) batteries. When the battery is fully charged, unlike the constant voltage chargers, the charging current will not decrease but will remain constant. Any charge after the battery is fully charged will result in increased battery temperature and gassing.

Taper Current Chargers

Taper current chargers have no controlled voltage or current. Their charging voltage and current depend solely upon the battery demanding the charge. The only limit to a taper current charger is its designed power capability. As the voltage increases, the charge current typically will decrease or taper off to a minimum. At the minimum current, the battery is fully charged and the current merely is wasted as heat. The charging voltage depends on the charging current and the charging power demanded by the battery or its maximum power. When the battery is fully charged by a taper current charger, it will attain a maximum voltage which is dictated by the chemistry of the battery and a minimum current input.

Automatic Chargers

Automatic chargers have included within them circuits which sense battery voltage and turn the charger off when the battery reaches or approaches the fully charged state. Since charge voltages depend on battery temperature, the control must include a temperature sensing and correcting means. Ideally the control should also sense polarity and prevent charging and sparks if the charger clamps are inadvertently connected in reverse. Automatic chargers are generally recommended because they can provide a safe, full charge with limited operator skill or knowledge.

High Rate or Boost Fast Chargers

High rate fast chargers are able to provide high charging currents regardless if the current is used to convert the battery’s active material or not. A charger that can put out over 40 amperes continuously is considered a high rate fast charger. The fast charging rate is usually greater than the active material conversion rate. With high rate chargers, battery overheating and gassing is likely if the charger is left unattended for too long. It is for this reason that most fast chargers come with a timer for cut off. The reason for high rate fast chargers, sometimes referred to as boost chargers, is to quickly charge a discharged, but good battery, in order to start a vehicle. It is not recommended for unattended or long term recharge of a battery.

Trickle Chargers

Trickle battery chargers are small current chargers. Normally, their charging rate is less than one ampere per battery, and sometimes less than 0.03 amperes per battery. A trickle charger cannot charge a completely discharged automotive battery. Its sole purpose is to maintain a battery at its full state of charge, over a long period of time, by replacing its self discharged capacity. However, a small current over a long period of time for a fully charged battery does promote grid corrosion.

Learn more about our revolutionary PFX Technology, an advancement in flooded cell battery technology utilized by no other battery manufacturer. Highly refined lead combined with continuous paste mixing technology and expanded grids bring customers a battery that outperforms competitors.