Applications for the challenages

Our custom label and Superlex® Premium Power commercial batteries cycle harder and crank stronger in the most difficult conditions. Designed to excel in high-heat, high-cycling applications, our Heavy Duty and Severe Duty Series are optimal for over-the-road trucks and construction equipment. Performance is enhanced in our Group 31 Severe Duty Series by a glass mat, which is embedded within the positive plate for extended cycling and rechargability.

Superior's Superlex® and custom label commercial batteries feature our PFX Technology and Grid-Loc Technology, which work together to create a vibration resistant battery that outperforms others in extreme weather conditions.

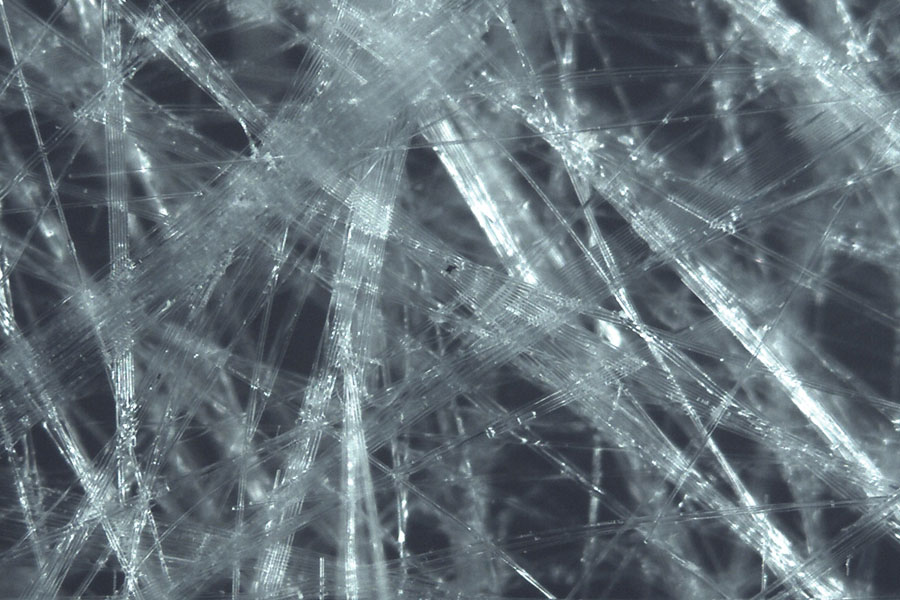

Fusing a glass mat with the positive plate in our Severe Duty Series allows for extended cycling use and rechargability. The glass mat reduces paste shedding, which increases the battery's life and performance.

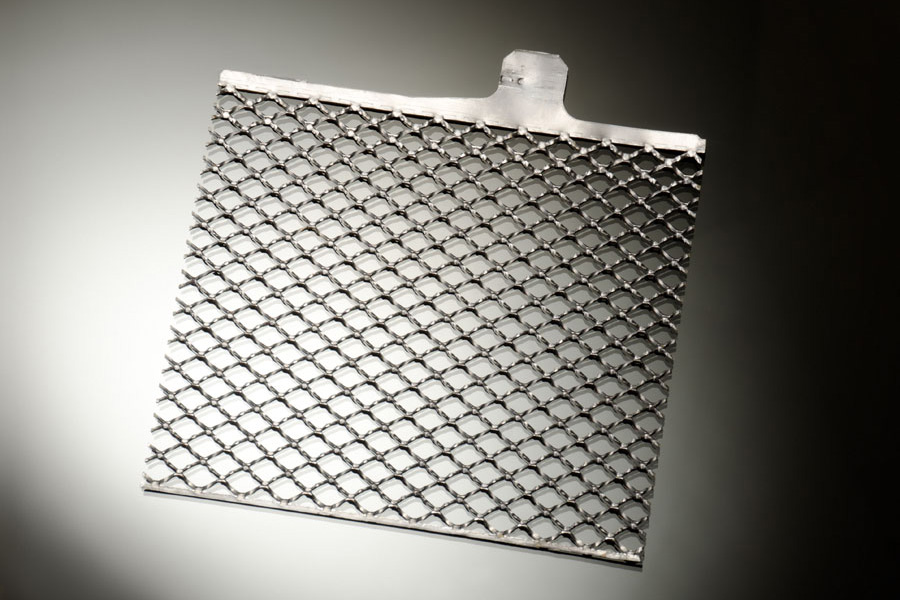

Superior's lead is cleaned of unstable contaminants before it reaches our facility, leaving only the chemical elements that guarantee excellent battery performance. Through an in-house, quality-controlled process, we manufacture the lead alloy used in our batteries, establishing the right chemical composition to decrease corrosion, reduce grid growth and increase battery life. Each roll of cast lead strip is inspected to ensure it meets Superior's proprietary metallurgical and electrochemical performance standards.

Superior's expanded positive grid construction provides increased cycle life to our commercial battery line.

Our patented Grid-Loc Technology™ for commercial applications features an internal cell bonding process, which locks the terminal post to the cell wall across the straps to prevent it from disconnecting from the cover button burn areas. This also prevents grid lugs from breaking and creates vibration resistance that excels in SAE J930 vibration testing.

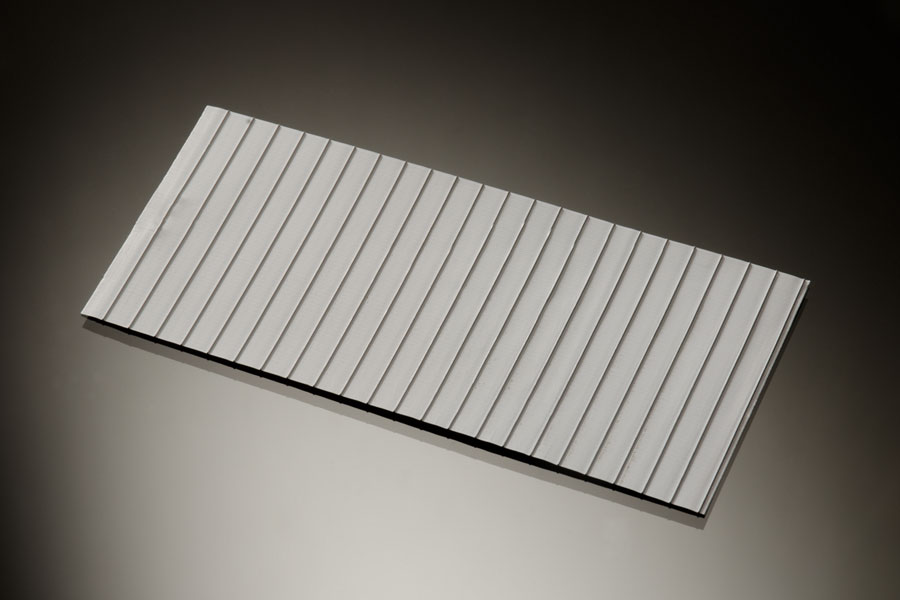

Superior and Superlex® batteries feature the Daramic® Duralife high-performance polyethylene battery separator. This separator extends battery life, enhances cyclability and improves paste-to-lead bonding performance.

Though components are manufactured daily, the vast majority of our batteries are not formed — or filled with electrolyte solution — until an order is placed. Validated by date stamp, this unique feature of Superior and Superlex® batteries means our distributors are getting batteries in the earliest stage of life, and consumers are experiencing fresher and longer battery performance.

Increased active material in our commercial plates provides the best reserve capacity ratings in the industry. Plates are cured in micro-process controlled, state-of-the-art hydroset curing chambers. These chambers precisely control all humidity, heat and drying during different stages to have an exacting cure of the plates.